News

Steelworks

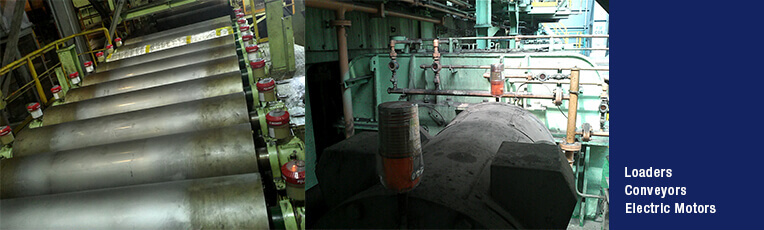

A modern integrated steel mill has the following functions for the production of primary steel products:

- - production of iron (conversion of the mineral in liquid iron)

- - manufacture of steel (conversion of cast iron into liquid steel)

- - melting (solidification of the liquid steel)

- - roughing / rolling billets (reducing the size of the blocks)

- - lamination of the product (finished forms).

The steel mill is one of the sectors in which the automatic lubricator is widespread and prevalent due to various inaccessible places for maintenance workers. Because of its enormous ladder, a modern steel mill is staff-free and completely automated. The length of transport systems that carry iron ore, coal (coke) and limestone usually reaches several kilometers. The steelworks equipment works in various conditions; with extremely low temperatures at high temperatures, from low speed to high speed, severe dust contamination in a wet vapor environment. The premature failure of the non-lubricating bearing. Some steel mills are small but have many rotary equipment suitable for automatic single point lubricators such as conveyors, motors, traction pads, etc. Not only do the larger steel mill need the greaser, but even the smallest steel mills equipped with many rotational equipment need the use of the automatic greaser advantageously.